[ 16.09.2021 ]

Common types of packaging for components and equipment:

Bulk

Drops, in bulk.

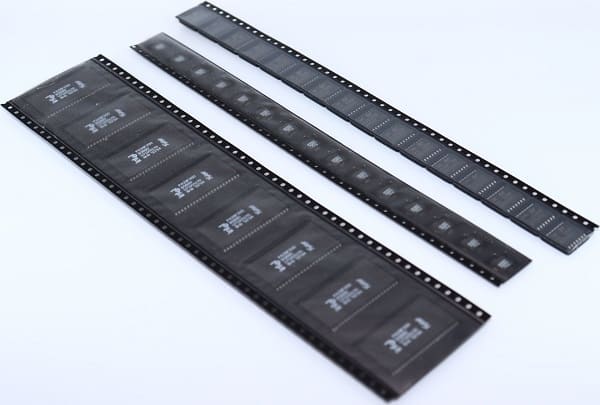

Tape & Reel (TR)

Packing of components on tape which is wound on a reel. Most often used for packaging SMD components.

Cut Tape (CT)

Cut Tape & Reel. Most often a piece of SMD component tape cut from Tape & Reel. Does not contain a threaded end at the beginning of the tape (leader) and an empty section at the end of the tape (trailer).

Digi-Reel

The packaging is similar to Tape & Reel, but the quantity of components is made to order. Usually cut from the manufacturer's packaging. An order for an item in this packaging cannot be cancelled or returned.

Tube (Rail, Rail/Tube)

Tube. Most often looks like a plastic ruler for storing microcircuits and relays and other components with 2 rows of pins (DIP enclosures).

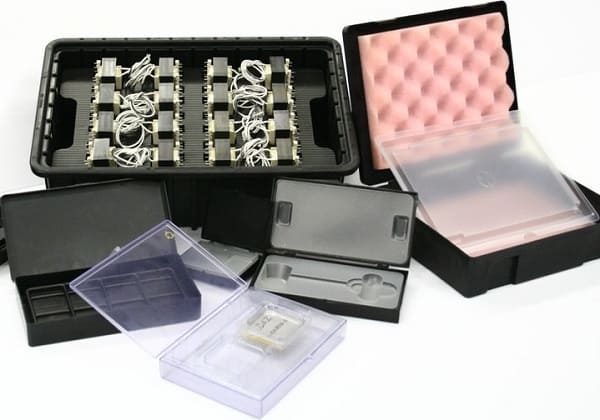

Tray

Tray. Typically used to store microchips in square packages (QFN and BGA). Unlike Tube, where chips are stored in a single line, Tray stores chips in multiple rows in a single plane.

Tape & Box (TB)

Tape in a box. A piece of ribbon in a box containing parts that are stacked in layers or coiled. The tape is usually pulled through an opening in the box.

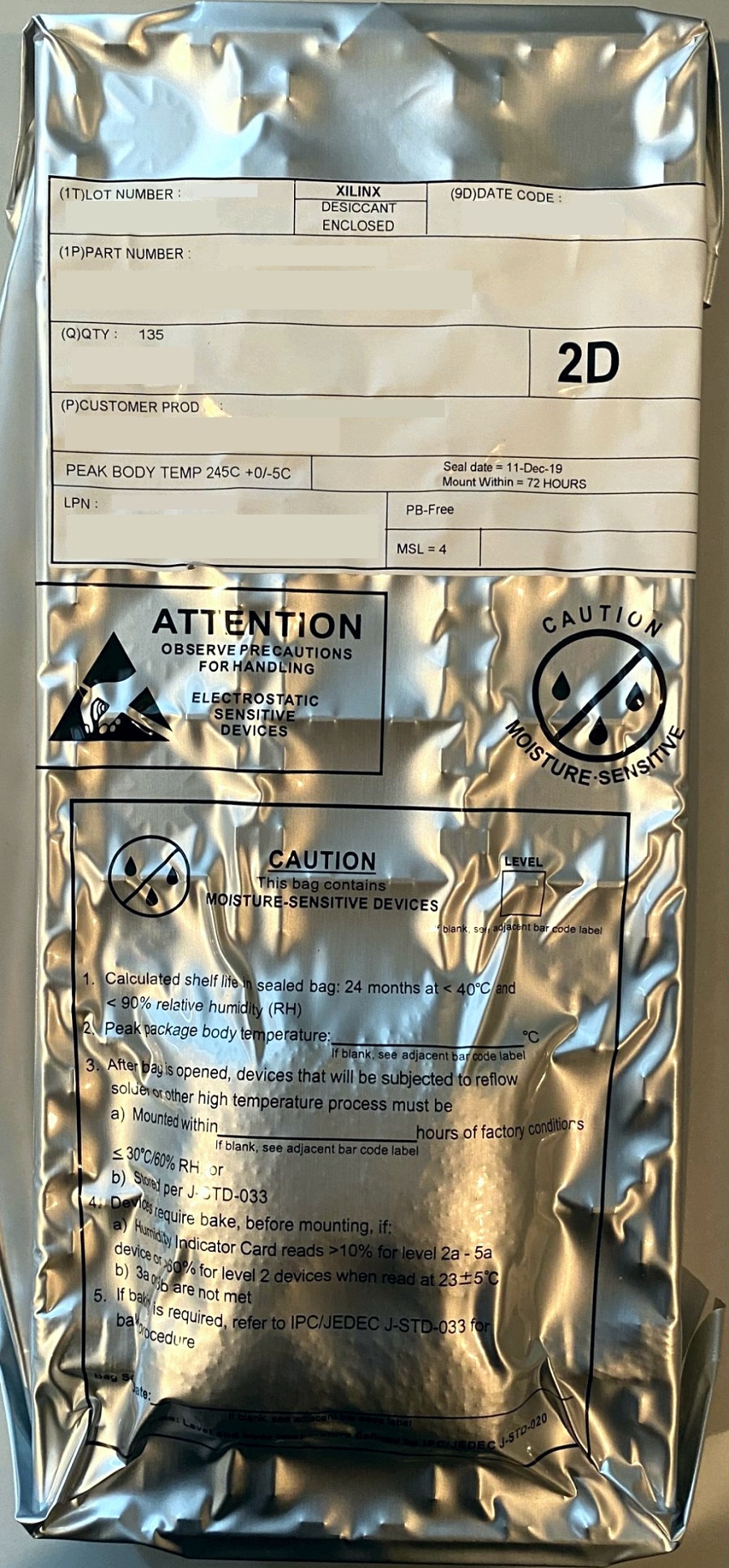

Bag

Packaged in a sealed sealed bag from the manufacturer.

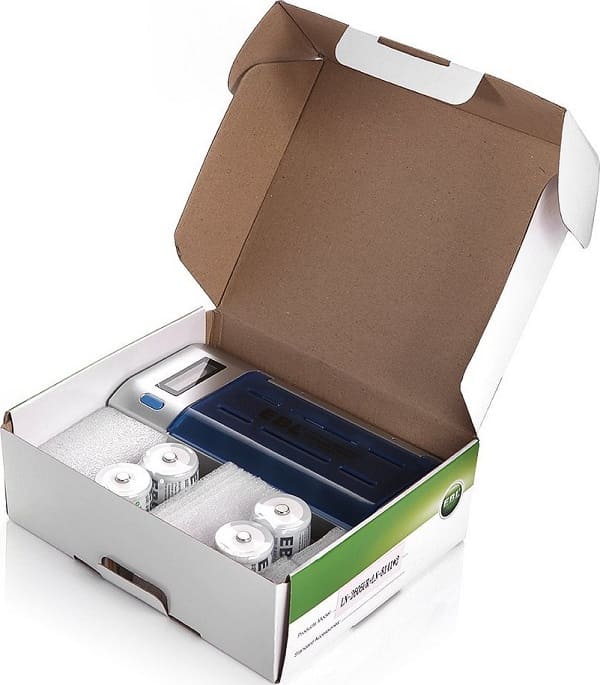

Box

Box. Paper, cardboard or plastic packaging from the manufacturer with the quantity of goods corresponding to the minimum quantity to be shipped, usually 1 piece.

Strip

Strip, contoured, non-returnable packaging. The goods in it are sealed between two flexible packaging blanks. The blanks are most often made of plastic, paper or aluminium tape. The products are removed by tearing or opening the package. A well-known example is the packaging of tablets in blister packs. In addition to unit packs, products can also be packaged in tape format, which have been pre-cut to the required length by the manufacturer.

Spool

A reel or bobbin for winding wire, cable, rope, ribbons, solder wire and other material, the length of which is considerably longer than other measurements.

Digi-Spool (Continuous Spool)

A piece of wire, cable, rope, tape or other material cut from a manufacturer's reel, custom-cut to a length significantly greater than other measurements. This section must be continuous.

Retail Package

Retail packaging. Packaging for retail sale, often a blister. Characterised by a brightly coloured print designed to attract the retail customer.

Case

A purpose-built protective cover or universal protective box with compartments for storing several components or parts of a single device.

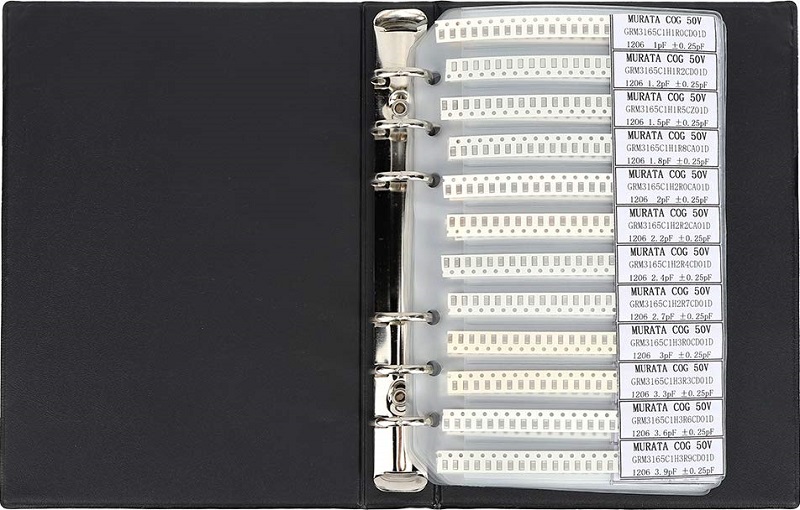

Book

Book. Packaging in the form of a book or segregator with pages, each of which contains a product.

Packaging and labelling of cable products:

In the production of cable products, special attention is paid to packaging and labelling, as this affects the integrity of the product and facilitates its identification.

The packaging of cable products must provide reliable protection against external influences, prevent mechanical damage and keep the goods in good condition throughout the entire storage and transport process. Different types of cables and wires may require specific types of packaging appropriate to their characteristics.

The marking of cable products must contain the information necessary to identify the product, such as:

- Name and brand of the cable or wire.

- Type and cross-section of the conductor.

- Length of cable or wire in metres.

- Date of manufacture.

- Manufacturer and country of origin.

The marking on the product should be clear and easily readable, weather and mechanically resistant. If necessary, additional markings indicating other characteristics of the product are permissible.

Packaging and labelling of electrical products:

Electrical goods and electrical equipment have special packaging and labelling requirements, as they are directly linked to operational safety and product quality.

The packaging of electrical goods and electrical equipment must provide reliable protection against mechanical damage, moisture, dust and other adverse influences. Depending on the characteristics of the products, different types of packaging may be used: cardboard boxes, plastic containers, blister packs, etc. The packaging must be durable, easy to use and provide quick access to product information.

The packaging of electrical goods is divided into several types: inner packaging, transport packaging, cushioning and fixing agents.

Inner packaging is designed to preserve the applied preservation agents and protect them from mechanical damage. Transport packaging, in turn, protects the products and inner packaging from mechanical and climatic factors, as well as provides convenience of loading and unloading, transportation and warehousing. Cushioning means are intended to protect the products from shock and vibration overloads, and fastening means - to prevent damage to the products and packaging due to inadmissible movements of the products inside the package.

Products or their components transported as separate packages may be unpacked as a whole, if the design features of the product, its preservation, conditions of transportation and storage and the shelf life allow it. If necessary, the individual parts of the products are protected by means of preservation agents and/or partial packaging.

The marking of electrical goods and electrical equipment must contain all the information necessary to identify the product and ensure its safe use.

The quantity of marking data to be affixed to each product shall be kept to a minimum. Composition and content of main and additional marking data shall be specified in standards, technical specifications for specific types of products or in design documentation. Special requirements to product marking shall be established by agreement between the manufacturer and the customer.

The main elements of marking include:

- Name and model of the product.

- Technical specifications (voltage, current, power, etc.).

- Date of manufacture and expiry date.

- Information on certification and conformity to standards.

- Operating instructions and safety warnings.

Additional marking data may include: serial number of the product; degree of protection; name of the country of manufacture.

Packaging of electronic components:

Electronic components and radio components are sensitive components which can be damaged by external influences. For this reason, the packaging of electronic components must be particularly safe and secure.

The packaging of radio components and components must protect them from mechanical damage, electrostatic discharges, moisture, dust and temperature fluctuations. Depending on the characteristics of the components, different types of packaging can be used:

- Anti-static bags and containers for protection against electrostatic discharges.

- Vacuum packaging to prevent oxidation of the contact surfaces.

- Heat shrink wrapping to ensure a tight adhesion of the packaging to the components.

- Foam boxes, cardboard boxes with dividers or special trays for storage and transport.

The labelling of electronic components should contain the information necessary to identify the product and ensure its correct use. The main elements of the marking include:

- The name and model of the component.

- Technical specifications (nominal voltage, current, capacitance, resistance, etc.).

- Information on the manufacturer and country of origin.

- The date of manufacture and shelf life.

- The marking may be applied directly to the component, to the packaging or to the accompanying documentation.

Conclusion

The packaging and labelling of electrical goods, electrical equipment, electronic components and electronic products plays an important role in ensuring the quality and safety of these products. Reliable packaging protects sensitive components from mechanical damage, moisture, dust and other influences, and properly executed markings contain all the information needed to identify and properly operate the product.

When designing packaging and labelling, it is important to consider the characteristics and requirements of each product, and to follow industry standards and guidelines. A comprehensive approach to packaging and labelling improves customer satisfaction and reduces the risks associated with poor-quality products and misuse.